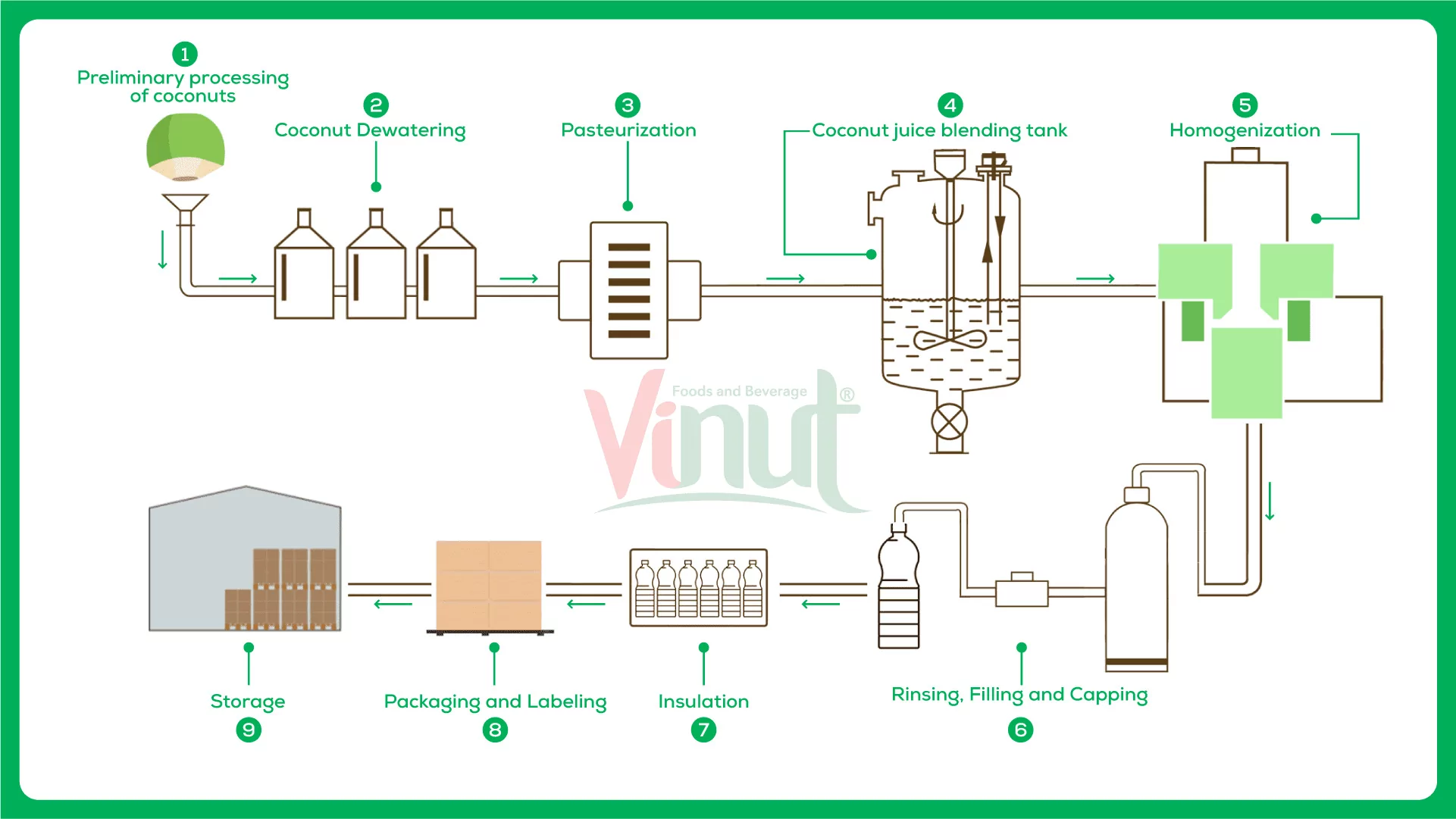

Production of Coconut Water Drinks

1. Harvest coconuts

Fresh coconut reaches the right ripeness. According to research, the most suitable time to harvest coconuts to use for canning purposes is when the coconut reaches maturity at 8 – 10 months old. We have coconut water from coconuts to produce canned/bottled coconut water. The sweetness of coconut water depends on the age of the coconut, the variety of coconut and the conditions where it is grown.

2. The production of canned coconut water at the factory

Preliminary processing of coconuts -> Coconut Dewatering -> Pasteurization -> Coconut juice blending tank -> Homogenization -> Rinsing, Filling and capping -> Insulation -> Packing and labeling -> Storage

3. Preliminary processing of fresh coconut

In order to completely remove dust and dirt on coconut shells during harvesting and transporting, the coconuts are dumped into the tank and immersed in a bath of water at room temperature. Then the coconuts are transferred through a system of pressurized water jets before being transferred to the coconut dewatering unit.

4. Coconut dewatering

Coconuts after washing are transferred to the coconut dewatering unit. Coconuts are placed on the cutting table with automatic cutters to be cut in half. Underneath the cutting table is a tank with a filter. Coconut water is passed through a filter to remove residual impurities from the coconut body and shell. The coconut water tank is directly connected to the pipeline system to transfer coconut water to the tank for the pasteurization process.

5. Pasteurization

Coconut water is transferred through pipes that move through the pasteurization area at a high temperature of 75oC – 110oC to destroy the microflora. Coconut water is fully preserved in taste quality and nutritional properties.

6. The pasteurization process is divided into:

- Low temperature pasteurization: Coconut water is exposed to a temperature of 60 to 75oC for a long time

- High temperature pasteurization: Coconut water is exposed to a temperature of 75 to 100oC for a shorter time.

7. Coconut juice blending

Coconut water from the pasteurization system is transferred to an average 100oC blending tank to blend the ingredients of the coconut water (coconut pulp and natural flavors depending on the product) and remove microorganisms for the last time.

8. Homogenizer

After being cooked, the coconut water will be transferred to the homogenizer to mix the ingredients added in the coconut water to increase the flavor and nutrition of the product. The homogenizer helps to keep the quality of coconut water the same throughout the shipment.

9. Rinsing, Filling and Capping

Coconut water from the homogenization system is filling into bottles and cans according to a predetermined capacity before being transferred to the capping line, officially completing the stage of putting coconut water into the container.

10. Insulation

Once the cans/bottles of coconut water are capped, the product is moved to an insulated area to cool and test the product before being sent to the packaging and labeling department.

11. Packaging and labeling

After reaching room temperature, the product is transferred to the packaging line and labeled to ensure accurate and complete product and manufacturer information. Consumers can trace the origin of the products.

12. Storage

Finished packaged products are transferred to the warehouse for counting and storing before being delivered to customers and distributed to the market.