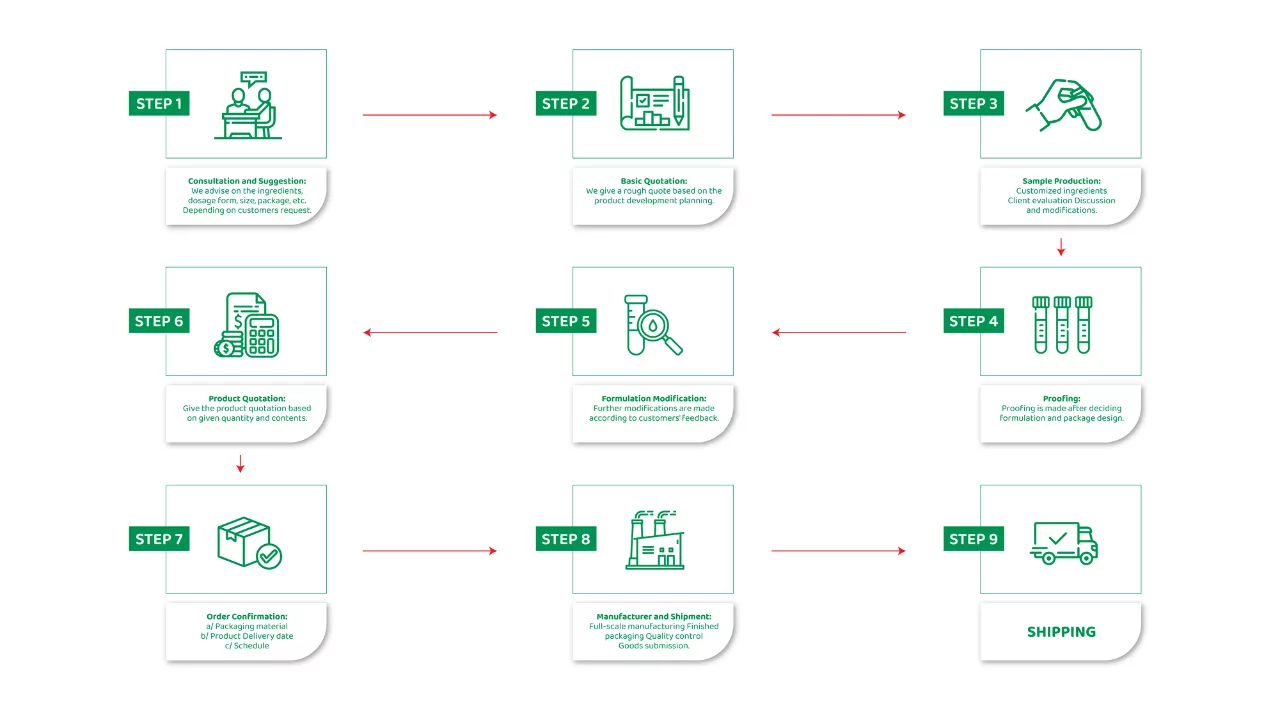

9 Steps to Launching Your Own Fruit Beverage Line with Nam Viet Foods & Beverage

Summary

Starting your own fruit beverage line can be a rewarding and profitable venture, but it requires careful planning, formulation, and production. Whether you're a startup looking to enter the beverage industry or an established brand aiming to expand, a structured approach is essential.

At Nam Viet Foods & Beverage, we provide OEM/ODM beverage solutions, helping businesses develop, produce, and distribute high-quality fruit beverages. Our step-by-step process ensures that your product is tailored to meet market demands, regulatory standards, and consumer expectations.

Step 1: Consultation and Suggestion – Laying the Foundation

Before production begins, it’s crucial to define the vision and goals of your fruit beverage. At Nam Viet, we take a strategic and collaborative approach, ensuring that every aspect of your product is carefully crafted to align with market trends, consumer preferences, and your brand identity.

- Product Idea: What kind of beverage are you envisioning? Whether it’s 100% pure fruit juice, a refreshing tropical blend, an energy-boosting fruit drink, or a functional health beverage, we help refine your concept to match consumer demand and industry trends.

- Target Audience: Understanding your audience is key to product success. Are you catering to health-conscious consumers, children, athletes, or premium buyers? Each market segment has distinct preferences, and we’ll guide you in tailoring flavors, ingredients, and packaging to meet their expectations.

- Unique Selling Proposition (USP): What makes your beverage stand out in a competitive market? Whether it's organic ingredients, added vitamins, low-calorie formulas, exotic fruit blends, or innovative functional benefits, we help define your differentiating factors to attract the right customers.

- Packaging Preferences: The right packaging enhances convenience, shelf appeal, and brand identity. Choose from: Glass bottles, PET bottles, Aluminum cans.

Our team of industry experts, R&D specialists, and market analysts will work closely with you to ensure your product concept aligns with consumer demand, emerging trends, and regulatory standards. From ideation to execution, Nam Viet is your trusted partner in bringing innovative, high-quality fruit beverages to life.

Step 2: Basic Quotation – Understanding the Costs

Once your beverage concept is finalized, we move into the cost estimation phase—a crucial step ensuring your product aligns with your budget and market expectations. At Nam Viet, we believe in complete cost transparency, allowing you to make informed decisions before entering full-scale production.

- Preliminary Price Range – We provide an estimated cost per unit based on key factors such as ingredient selection, packaging type, production complexity, and order volume. Whether you’re using premium organic fruits, functional additives, or specialized packaging, we help you understand how each element impacts pricing.

- Product Development Quotation – You’ll receive a rough quotation covering formulation, raw materials, and production costs, allowing you to plan your budget effectively. This helps determine whether adjustments are needed before moving forward.

- Full Cost Transparency – We break down all cost components, enabling you to fine-tune your recipe, packaging choice, or order quantity to achieve the best balance between quality, pricing, and market competitiveness. If needed, our experts will provide alternative solutions to optimize costs without compromising on product excellence.

This step ensures that your fruit beverage is financially viable before committing to full-scale production. It provides a clear roadmap for investment, helping you make strategic decisions that align with your business goals, target market, and profit margins.

Step 3: Sample Production – Creating Your Prototype

With your product concept and budget finalized, the next step is to develop a prototype sample—a crucial phase where we transform your vision into a tangible product. This process ensures that your fruit beverage meets your exact taste, texture, and quality expectations before moving into mass production.

- Selecting High-Quality Ingredients & Customizing Flavors – We carefully choose premium fruit ingredients and natural extracts to create a rich, authentic taste. Our formulation experts work with you to fine-tune the sweetness, acidity, and overall flavor balance to achieve the perfect profile.

- Taste Tests & Texture Evaluations – We conduct multiple sensory tests to analyze how your beverage tastes, feels and performs. From mouthfeel to aroma, we ensure every sip delivers a consistent drinking experience.

- Client Feedback & Refinements – Once the initial sample is developed, we send it to you for evaluation. Your direct feedback helps us make any necessary adjustments, whether it’s modifying the flavor intensity, ingredient ratio, or functional additives. Our goal is to ensure the final product aligns perfectly with your brand’s vision and market expectations.

This step allows you to test and approve your beverage before large-scale production, ensuring that it meets consumer preferences and quality benchmarks. By fine-tuning the taste, texture, and formulation, we eliminate potential issues early, saving time and resources in the long run.

Step 4: Proofing – Finalizing Formulation and Packaging

Once your sample is approved, we move into the proofing stage—a critical step that ensures your beverage is fully optimized, compliant, and market-ready. This phase allows us to fine-tune every detail before full-scale production, minimizing risks and ensuring consistency, quality, and consumer satisfaction.

- Finalizing the Beverage Formulation – We make any necessary adjustments to sweetness, acidity, and nutritional content to achieve the perfect balance of flavor, texture, and health benefits. Whether enhancing the mouthfeel, natural taste, or functional properties, our team ensures your beverage meets consumer expectations and industry standards.

- Perfecting the Packaging Design – From label accuracy and branding consistency to packaging material selection, we ensure your product meets both regulatory requirements and aesthetic appeal. Our experts verify that your design elements, nutritional claims, and product information are compliant with local and international food regulations.

- Shelf-Life & Stability Testing – To guarantee product freshness and quality over time, we conduct rigorous shelf-life and stability tests. These tests evaluate how factors like temperature, light exposure, and storage conditions impact your beverage, ensuring it remains safe, flavorful, and visually appealing throughout its intended shelf life.

This stage ensures that everything is perfected before large-scale production begins, preventing unexpected challenges such as flavor inconsistencies, labeling errors, or shelf-life concerns. By addressing these factors early, we guarantee a smooth transition to mass production while maintaining the highest levels of quality and brand integrity.

Step 5: Formulation Modification – Refining the Product

Even after the proofing stage, some final tweaks may be needed to ensure your product is fully optimized for consumer appeal, quality, and market competitiveness. The adjustment phase allows us to refine those details, ensuring everything is perfect before moving into mass production.

- Final Flavor and Ingredient Adjustments – This is your last opportunity to make any minor adjustments to the flavor profile, ingredient ratios, or packaging. Whether it’s adjusting the sweetness level, acidity, or texture for a smoother taste, we make sure your product matches your vision while appealing to your target market.

- Market Positioning Adjustments – Based on consumer feedback, market trends, and target audience preferences, we might recommend some final adjustments in positioning to ensure your beverage is aligned with current market demands. Whether it’s modifying the price point, health benefits, or unique selling proposition (USP), we help optimize your product’s market fit.

- Regulatory and Quality Assurance Checks – Ensuring your product meets all quality and safety regulations is non-negotiable. During this phase, we conduct a final review of your beverage’s compliance with industry standards, including testing for safety, labeling accuracy, and nutritional claims.

This step guarantees that your fruit beverage is perfectly fine-tuned and optimized for success in a competitive market. By addressing any last-minute adjustments, you ensure a smooth, hassle-free transition into mass production, reducing the risk of any quality or market alignment issues post-launch.

Step 6: Product Quotation – Getting the Final Cost Estimate

Once your formulation and packaging are finalized, we provide a detailed quotation to give you a clear understanding of the total production costs. This step ensures financial transparency, allowing you to make well-informed decisions before proceeding with mass production.

- Ingredient Costs – A breakdown of expenses for essential components such as fruit concentrate, natural sweeteners, functional additives, and any other ingredients tailored to your beverage formula.

- Packaging Costs – The pricing for selected bottles, cans, labels, shrink sleeves, printing, and any custom packaging elements.

- Production & Labor Costs – A complete cost assessment of manufacturing, filling, quality control, and other production-related expenses.

- Minimum Order Quantities (MOQs) – Information on MOQ requirements to ensure cost-effective production while meeting your market demand

This final quotation provides full cost transparency, helping you align production expenses with your budget and business strategy. By having a clear financial overview, you can make necessary adjustments to ingredients, packaging, or order volume to optimize your pricing and profitability.

Step 7: Order Confirmation – Preparing for Production

With all the details finalized, we’re ready to move forward to the order confirmation phase—a critical step in preparing for large-scale production. This ensures that every aspect of your beverage is ready for efficient, high-quality manufacturing, with no surprises along the way

- Finalizing Packaging Material Selection – We confirm the final choice of packaging materials, ensuring everything aligns with your branding and product specifications. Whether you’ve chosen glass, PET bottles, or aluminum cans, we ensure that quality, durability, and aesthetic appeal are maintained throughout production.

- Setting a Production and Delivery Schedule – We work closely with you to establish a clear production timeline and set realistic delivery expectations. This includes coordinating all logistics, from raw material sourcing to shipping and distribution, ensuring that your product is delivered on time and within budget.

- Ensuring Legal and Compliance Paperwork – To ensure smooth and timely production, we review and finalize all necessary legal documentation, including regulatory approvals, health certifications, and labeling requirements. Our team ensures that your product is fully compliant with local and international standards, leaving you with peace of mind.

Once your order is confirmed, we begin the final preparations for large-scale production, ensuring that everything runs smoothly from start to finish. By addressing all the logistical, regulatory, and quality-related factors in this phase, we guarantee that there are no delays or compliance issues once production begins.

Step 8: Manufacturing and Quality Control – Bringing Your Beverage to Life

At Nam Viet, we take pride in our advanced, certified manufacturing facility, where every step of the production process is designed to deliver precision, consistency, and superior quality. Our fully automated production lines are equipped with cutting-edge technology to streamline operations and meet the demands of large-scale manufacturing without compromising on quality.

- Automated Production Lines – Our highly automated systems ensure that each step of the production process is precise, efficient, and consistent. This allows us to maintain uniformity across all batches, meeting the highest standards of quality and flavor for every beverage.

- Rigorous Quality Control Checks – Every batch undergoes strict testing and inspection to ensure it meets the highest quality and safety standards. These checks include:

- Ingredient Testing – We test every ingredient for purity, authenticity, and sourcing quality to guarantee that only the best ingredients go into your beverage.

- Microbiological Testing – Each batch undergoes microbiological analysis to ensure the product is safe for consumption and free from harmful pathogens.

- Packaging Integrity Tests – We conduct thorough tests to ensure that all packaging is secure, leak-free, and defect-free, safeguarding the quality of your product throughout its shelf life.

At Nam Viet, quality and safety are at the core of our operations. Our manufacturing facilities adhere to strict global food safety regulations and hold internationally recognized certifications, including: BRCS, FDA, KOSER, GMP- EU Organic and USDA Organic - HALAL GCC and, FSSC 22000, HACCP -WCA Report, GVS Report, SMETA Report, and ISO 14001:2015.

Step 9: Shipping and Delivery – Bringing Your Product to Market

Once your beverage has passed through production and quality checks, we move on to the final stage: packaging, labeling, and preparing for shipment. This ensures that your product is not only market-ready but also protected and attractive for consumers.

- Global Distribution Support – We provide comprehensive logistics and distribution support, ensuring that your product reaches the right destinations. Whether you’re targeting local markets or expanding internationally, we handle customs clearance, shipping coordination, and all the necessary steps to ensure smooth, timely delivery to destinations around the world.

- Packaging and Labeling – Once the product is ready, it’s carefully packaged and labeled to ensure that it complies with regulatory standards and showcases your brand identity. From barcode scanning to ingredient declarations and nutritional information, every detail is checked to guarantee accuracy and appeal.

After packaging and labeling, your finished fruit beverage is prepared for shipment. We make sure your product is stored and shipped in optimal conditions to maintain its freshness and quality throughout the process.

Why Partner with Nam Viet Foods & Beverage?

Launching a fruit beverage brand requires expertise, advanced production technology, and strong industry knowledge. Here’s why Nam Viet is your best partner for OEM/ODM beverage production:

- Full-Service OEM/ODM Solutions – From formulation to packaging.

- Customizable Formulations – We tailor products to your taste preferences and market needs.

- High-Quality Standards – Certified ISO, HACCP, and GMP facilities.

- Experienced R&D Team – Helping you create unique, market-ready beverages.

Request Free Samples – Try Before You Buy!

Please fill out the form below to request your free samples. Our sales team will contact you for confirmation.

Juice Concentrate

Juice Concentrate Vegetable juice

Vegetable juice Juice Milk

Juice Milk Stand Up Pouches

Stand Up Pouches